How $65M Logistics operator decreased costs by 20% while paying their workforce more and boosting average worker efficiency by 15%

“My team embodies what operational excellence truly means. With Kardamon we’ve found the missed element. We realized we’ve measured and counted productivity inappropriately. We recognise the new approach approach as a silent industry revolution”

Michal Babij,

Site Lead & Continuous Improvement manager, ex. Amazon

$65M Logistics operator

Automotive marketplace and logistics operator

Turnover: $65M

Warehouse team: 500 people

Operations monthly: 20 000 human-hours

The Challenges

Poor traceability — data scattered across systems and manually consolidated in spreadsheets, causing errors and leaving teams unable to identify issues, prioritize, or track progress.

Outdated operational norms — set manually and subjectively, becoming unfair and inaccurate over time.

Unfair motivation system — no precise way to identify top and low performers, leaving the workforce with little incentive to grow.

Inaccurate labor forecasting — weak models led to over- or understaffing, driving costs up and productivity down.

Inefficient averaged pricing — inflated margins for some customers but negative for others, creating heavy dependency on the mix of items handled.

The Results

Data foundation: Built unified, real-time dashboards — giving teams the ability to quickly spot bottlenecks, set priorities, and track progress.

Result:

+50% productivity growth from improvement initiatives.

Incentive overhaul: Implemented a new performance-based incentive system.

Result:

+15% operational efficiency in 4 weeks.

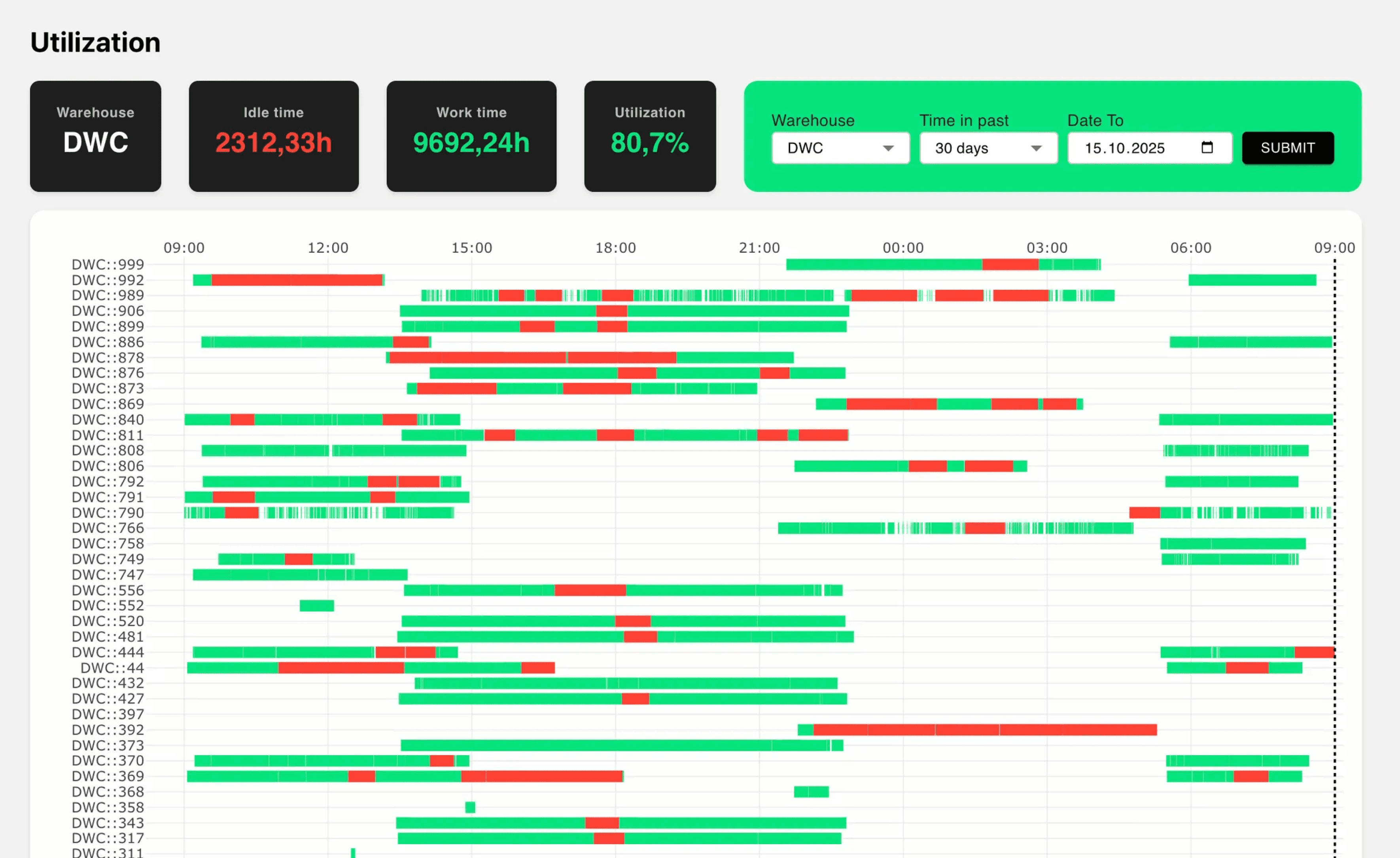

Utilization & Forecasting: Optimized labor allocation and forecasting models.

Result:

Utilization increased from 45% to 75% and 20% cost reduction in 3 months.

Financial Sustainability: Significantly improved financial efficiency

Result:

Gross margin 5% → 20% in 3 months

Step 01: Data foundation

Challenge

The first step was creating transparency by gathering and consolidating data.

Emex operated multiple WMS platforms, each with separate user logins and processes. Some systems were internally controlled, while others were third-party with no source code access.

Actions

Most warehouse operations could be described through a few key attributes:

Operation type — what action was performed

When — timestamp of the action

Who — the user

From / To — source and destination, including data on the container/box to which item was placed

Obj — the object involved, including qty/parcel type and other data

Using Kardamon’s operations and parsing engine, we unified data across all sources and enabled near real-time collection. For the first time in the company’s 20-year history, all operational data was stored in one place.

Step 02: Exploring the operations, setting up the norms, and the incentives

Results

01

An automated motivation system that retained top performers and encouraged low performers to improve

02

Employees gained daily visibility into their speed and efficiency, motivating them to experiment and optimize.

03

Managers could train underperformers directly, helping raise pay while boosting warehouse efficiency.

04

Average productivity increased by 15–25% across all warehouses within 4 weeks.

Challenge

Emex measured productivity using lines per hour and cases per hour. These metrics were tied to bonuses and workforce motivation.

The flaw: they ignored differences between item types. Forecasts became unreliable across customers and parcel types.

Example: packing the first item into a box required 90 seconds to prepare the box, while subsequent items took only 3 seconds. Operators handling bulky items were underpaid since they had to repeat box preparation more often.

Actions

We mapped all events and metadata to identify specific tasks performed by the workforce. Using the autonorming module, we have set performance standards at the 80th percentile of task completion times (in seconds).

Step 03: Enabling real-time control through web dashboards

Results

01

+50% additional productivity growth within six months

02

20% cost optimization while improving quality

03

Significant net margin expansion

Challenge

With multiple disconnected systems and no reliable efficiency tracking, Emex struggled to prioritize which processes to optimize.

Initiatives were judged subjectively and measured only at month-end through the P&L.

Actions

Within 4 weeks the platform was deployed across all five distribution centers via seamless plug-and-play integration, streaming live event data, and granting web access to all team members.

By comparing norms (expected task duration) with actual completion times, Emex gained real-time efficiency metrics.

Key metrics introduced:

Time spent — total human-hours per task

Average time per task

% of tasks within norm — deviation tracking

Productivity (norm ÷ time) — performance vs. standard

Utilization — percentage of useful time vs idle time

Benchmarking across warehouses and teams spurred knowledge transfer and launched new initiatives.

Visibility into timing and cost made it easy to prioritize the highest-leverage projects:

Box packaging process: +50% packing productivity

Picking process for marked goods: +200% picking productivity

Optimized placement strategy: +30% placement productivity, decreased error rate

Step 04: Forecasting the labor

Results

01

Utilization improved from 45% → 75% while meeting SLAs

02

Pricing model optimized with accurate norms and utilization benchmarks

03

Net margin grew from 5% → 20%

Challenge

Emex relied on manual forecasts based on average lines/hour and cases/hour. Manpower wasn’t adjusted to incoming orders, which fluctuated with seasonality and customer growth.

With new visibility, Emex discovered utilization was only 45%—meaning more than half of paid time was idle.

Actions

We introduced labor forecasting using norms, actual task times, and expected workloads. A data science–driven forecasting module gave managers precise insights into required labor hours by volume, date, and operation.

Conclusion

The collaboration with Kardamon became a turning point for Emex Logistics. What started as a search for operational clarity evolved into a full-scale transformation in the way the company managed, measured, and motivated its people.

With real-time data now available for every operation, Emex replaced assumptions with precision. Leaders could see exactly how much time and cost each activity required, identify inefficiencies instantly, and make informed decisions instead of relying on intuition. Within weeks, cost visibility became transparent, labor utilization rose from 45% to 75%, and total costs dropped by 20%.

Kardamon also changed the human side of operations.

Employees began to see their own performance metrics, understand what drives better results, and take ownership of their productivity. Management could finally reward top performers based on facts, not averages — creating a culture of fairness, motivation, and continuous improvement.

By combining data transparency, AI-based forecasting, and gamified motivation, Kardamon helped Emex achieve measurable gains in efficiency (up to 50% across distribution centers), improve workforce morale, and bring operational management to an entirely new standard.

Emex turned its warehouses into data-driven ecosystems — faster, smarter, and more human at the same time.